Pathway to resilience n ° 8: Develop local tools for storage and transformation

- 2020-02-01 09:34:30.0

- 14570

- tools, storage, transformation

The vast majority of food products have undergone one or more transformations: milling for flour, pressing for oil, fermentation for dairy products, slaughtering and cutting for meat ... The food industry is growing. is concentrated and most of the production now relies on large units, distant from farms and consumers. Limiting the food system's dependence on transport and fossil fuels therefore requires the relocation of processing units.

State of Affairs

Hyper-concentrated processing sectors

Processed products: a preponderant place in our diet

In regions of the world with marked seasonality, such as Europe, the main agricultural productions are irregular during the year. As most raw agricultural foodstuffs keep very poorly over time, it is essential to have storage and preservation resources to ensure a varied diet throughout the year. The primary function of processing is therefore to protect food products from bacteria, fungi, insects and other animals. It also makes it possible to preserve or even improve the nutritional qualities of certain foods (in particular through fermentation) and to obtain concentrated products that are easy to use (oils, sugar).

The transformation processes can be divided into three categories:

- The first transformation consists in stabilizing the food after harvest. These include, for example, drying, milling cereals, or extracting oil from the seeds.

- Secondary processing is applied to both fresh and first-processed products, resulting in a greater variety of foods. Examples are the manufacture of bread, dairy products, meat, fermented drinks, canned goods or frozen products.

- Finally, "ultra-processed" products are the result of numerous industrial processing steps and techniques, in order to obtain "ready-to-eat" meals.

About 80% of household food expenditure is on processed foods. A very large majority of our calorie intake is based on products that have undergone at least one or two transformations : flour, semolina, bread, pasta, oils, sugar, dairy products, meats, preserves. Only fresh fruits and vegetables, nuts, eggs, honey, and certain starches (potatoes and whole grains) can be eaten as is. However, they are also mostly processed (freezing, dehydrating, dehulling ...), especially to serve as ingredients in other food preparations.

The processing sector generates 600,000 jobs in France, of which around three quarters are in the agri-food industry and one quarter in the commercial charcuterie and bakery-pastry trades. That's about three jobs in processing for four farm workers!

Recent hyper-concentration

During the second half of the 20th century, processing activities were concentrated both economically and geographically . Following the trend observed in other industries, this concentration is explained in particular by the massive development of road and maritime transport, made possible by the abundance and low cost of oil. In this particular context, economies of scale have enabled a few large groups to prevail against a multitude of local or regional players. There are still many small food processing companies in France, whose supply and distribution channels are above all local, but in terms of volumes processed, the large industrial groups largely dominate the market: only 2% of companies represent 76% of the salaried workforce and account for 85% of the sector's turnover. They are based on very large-capacity processing units, which are supplied over long distances, and in return deliver their products throughout the country . The everyday food products presented below are a good illustration of this phenomenon of concentration.

Flour and bread

In a century, the number of mills has been divided by 100 , going from 40,000 at the start of the twentieth century to 6,000 in 1950, and to 394 in 2018. If the first phase of this decline s 'explained by technical advances (transition from stone millstones to cylinder mills), the second results from the development of very large industrial flour mills, supplied by a vast transport network. Today, only 34 mills produce half of the total volume of flour in France, and 95% of the volumes of cereals processed are in mills whose radius of activity exceeds the departmental scale.

Mill of the company GMS Meunerie, in Strasbourg (Bas-Rhin). Crédits : © Nis&For.

The sector has also become highly concentrated economically : four groups (NutriXo, Moulins Soufflet, Ariane Meunerie and Grands Moulins de Strasbourg) alone produce 51% of the flour made in France. They now integrate many links in the sector: sale of seeds and phytosanitary products, harvest, breadmaking, and sometimes retail distribution.

Dairy products

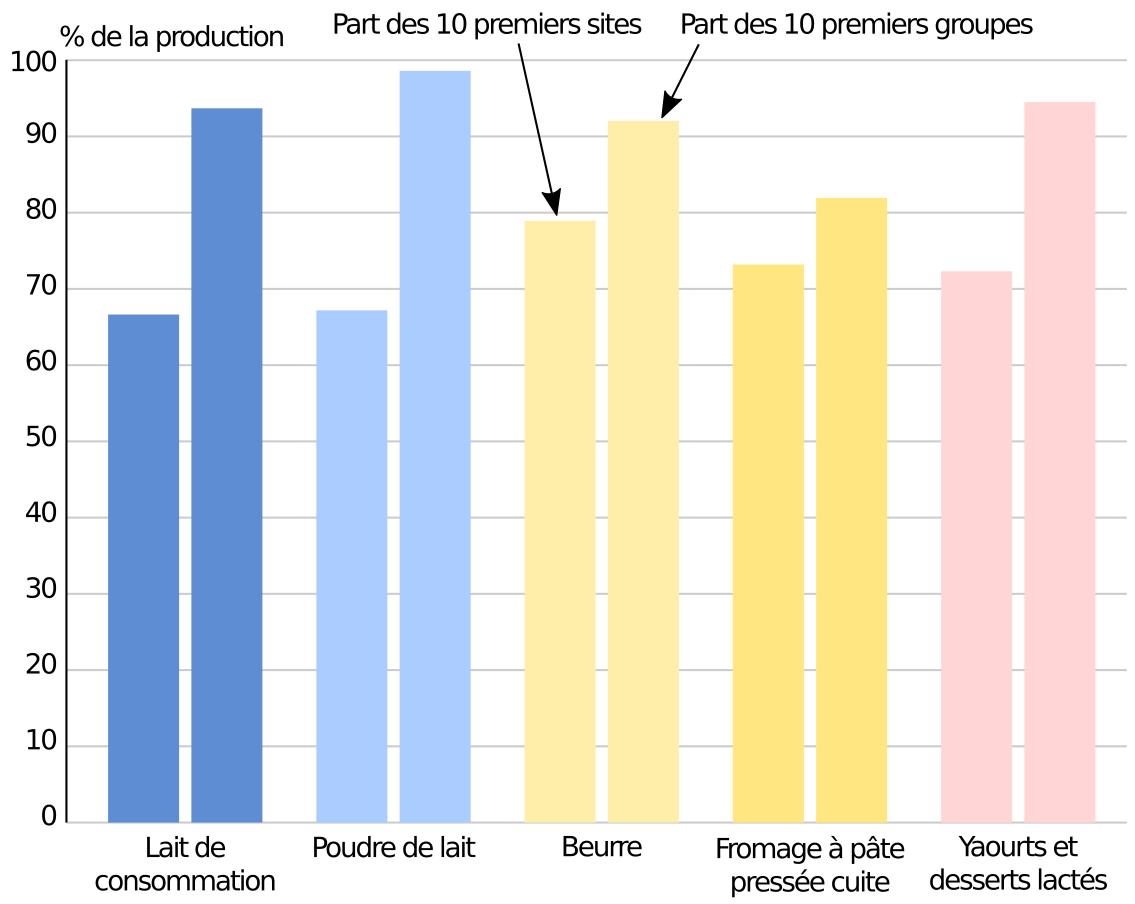

In France, more than one in two dairy processing units closed its doors in 20 years , between 1986 and 2006. Brittany and the Pays de la Loire account for a third of milk deliveries. Industrial and economic concentration is also high (Figure 26). The majority of production is based on around ten sites, controlled by a small number of industrial groups with considerable economic power: Lactalis, Danone, Sodiaal, etc.

Figure 26 : Industrial and economic concentration within the dairy products sector in France. The values represent, for five categories of dairy products, the share of national production provided by the top ten sites (left column) or by the top ten groups of companies (right column) .Source : Les Greniers d’Abondance, from FranceAgriMer (2016).

Meat

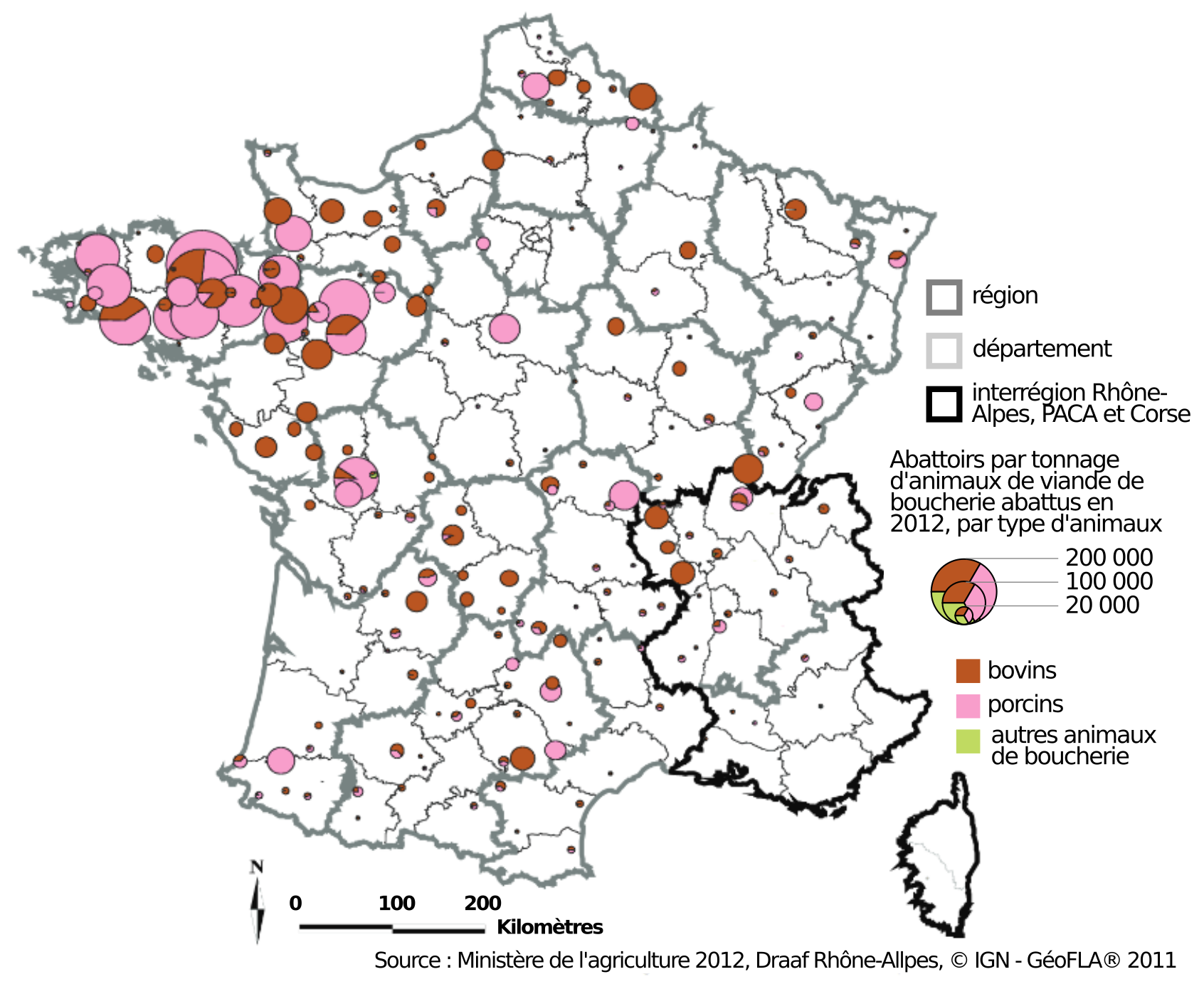

In 2008, half of the meat produced in France came from around twenty industrial slaughterhouses . Geographically, the sector is highly concentrated in the Great West (Figure 27). Local public slaughterhouses, municipal or inter-municipal, increased from 600 in 1980 to 100 in 2010 and their share of national volumes produced from 63% to 8% over the same period. The units of the Bigard group alone slaughter 43% of meat volumes each year.

Figure 27 : Map of slaughterhouses and slaughtered volumes. Source : Bonnet et Guittard (2017).

Consommation énergétique

The agro-food industries also have significant energy needs (see depletion of energy and mining resources). Of the same order of magnitude as the energy directly consumed on farms, 60% of these are based on fossil fuels (mainly natural gas).

Links to resilience ?

Associated threats : depletion of energy and mining resources, economic and political instability

As unprocessed products constitute a small part of our diet and for the most part keep very poorly, food security in a territory depends on the proper functioning of its processing channels. In the event of insufficiency or failure of the processing industries, the products concerned would sometimes be confronted with peaks of overproduction during which wastage would be very important, sometimes with periods of shortage.

The complexification of processing chains contributes to the lengthening and multiplication of transport stages. The scarcity of fossil fuels calls this paradigm into question , and poses a threat to this type of very centralized organization. The very large units, which drain agricultural production over a vast territory before selling the products processed on a national or even international scale, depend on a functional transport network and infrastructure at very low user costs. , and very cheap energy. A localized disturbance affecting a single large site can have disproportionate consequences for the entire food system. The dependence of the processing companies themselves on fossil fuels is also a factor of vulnerability .

Objectives

Dealing with the eventuality of constraints on transport chains requires diversifying the scales of processing sectors. This involves developing additional local units that can meet the basic needs of the population , by favoring tools that are easily repaired, inexpensive in energy and / or based on renewable energies (see resilience path no. 3).

In particular, it seems relevant to develop:

- at the farm level, primary processing workshops (dryers, canning factories, cheese factories, mills and bread ovens);

- at the scale of a municipality or an inter-municipality, tools of greater capacity, requiring more investment and allowing economies of scale (mills, oil presses, canneries, fixed slaughterhouses or mobiles);

- storage capacities associated with these units , making it possible not to operate in just-in-time.

It is interesting to pool this equipment between producers, processing professionals, communities and individuals in order to ensure their depreciation and operating costs. These processing units will provide direct outlets for local producers, offering them the possibility of diversifying their production with little investment. They can be made available to professionals or take the form of collective transformation workshops. These are generally led by a project leader, or an employee who supports the user or performs the transformation task alone.

Actionnable Levers

LEVER 1 : Carry out an inventory of existing processing units

This diagnosis should make it possible to identify the sectors that need to be supported or developed in the territory, by recording:

- the nature of the existing processing units;

- their capacity and scale of radiation;

- the level of adequacy with agricultural production and local needs.

Map of France for cereal processing and storage units, developed by Passion Céréales. LEVER 2 : Promote the development of processing and storage tools

Communities can mobilize their expertise in economic development to:

- Support project leaders by promoting their integration into the networks of local actors; by helping them find public or private funding (see Building and financing a food resilience project), and by directly facilitating their installation (provision of land or real estate, dedicated activity areas);

- Participate in the creation and proper functioning of cooperative societies;

- Make aid to businesses conditional on strengthening the food resilience of the territory.

- For this type of project, the various local rural development organizations are invaluable support (DRAAF, Chamber of Agriculture, Organic Farmers' Groups, InPACT pole). They can facilitate the link with producers, the assessment of supply needs and possibilities, the identification of obstacles, etc. The quality of the links between the services of a local authority and with neighboring territories is here an important factor of success .

The community of communes of Magnoac (Hautes-Pyrénées) financed the construction of a pasta-making workshop which receives durum wheat flour from local peasant seeds. This workshop took the form of a SCIC (Cooperative Society of Collective Interest), the Odyssey of Engrain, of which the community of municipalities is a member. Crédits : © l’Odyssée d’Engrain.

Created in 2010 in Balazuc (Ardèche), Le Bateleur is an association that offers to promote local productions with canned fruit or vegetables, cold meats or cooked dishes. For this, it offers a transformation workshop at the service of various users, such as citizens during collective transformation days open to all. Crédits : © Association Le Bateleur.

The Silo Bio Ouest (Charente-Maritime) is a structuring tool for the arable crops in organic farming in the region. It allows grain storage and on-site processing projects are under development. The communities participated in setting up and financing this project. The Silo Bio Ouest is located in the Val Bio Ouest business center in Saint-Jean d´Angély (Charente-Maritime). This center is dedicated to first and second processing companies and to production services related to organic food.

Crédits : © ValBioOuest - CDC des Vals de Saintonge

LEVER 3 : Use public procurement in collective catering

Public ordering of collective catering, when it primarily targets the local area, can directly support local production units economically by providing them with direct outlets(voir voie de résilience n°10).

LEVER 4 : Relocate an entire industry

Communities can structure a territorial sector from agricultural production to processing and marketing. This is a major lever for strengthening local food resilience . Several territories have thus embarked on the development of wheat-flour-bread sectors, such as the Perche Regional Natural Park (Eure-et-Loir) which has spurred the creation of a local bread brand, or the Uztartu agri-food cluster which has made it possible to revive wheat cultivation in the Basque Country and to develop an entirely local wheat / flour / bread sector.

In the Basque Country, The Herriko Ogia Association unites 25 farms farms, two flour mills and 60 bakeries to offer entirely local bread. This organization makes it possible to act on a large number of dimensions of the system: reduction of crop rotation in corn, and therefore of dependence on irrigation, supervision of supplier agricultural practices through specifications, development of seeds adapted to the terroir , economic maintenance of flour mills, less dependence on transport, etc. Crédits : © Uztartu.

Side Benefits

The development of local processing units allows the creation of jobs that cannot be relocated on the territory. The structuring of quality sectors ensures diversification and enhancement of income as well as the maintenance of specific know-how linked to local productions. Pooling and making tools available to farmers who want them allows a better distribution of the value created while achieving economies of scale . It also allows the development and strengthening of mutual aid networks.

Obstacles

Unfair competition

The economic concentration of the food industry allows large groups to invest massively in marketing and communication, and thus to consolidate their dominant position. Depending on the product, advertising represents between 5 and 15% of the final sale price. Here again, the effects of scale operate and benefit the large firms.

Economic model

A processing unit is a large investment, which can be difficult to pay off. In general, the more resilient models are often not the most profitable as long as the context remains sufficiently favorable to the industrialized model. Cooperative structures supported by local public policies and consumers can nonetheless constitute economically viable solutions.

Divergent interests

The agrifood industry has extremely strong economic and political power. Multiple oppositions can slow down the development of territorial projects going against their interests. The communities can play on the complementarity of the scales and the best remuneration of the farmers of the territory to reinforce the political legitimacy of these projects.

Weak support for local transform tools

Territorial transformation units suffer from a lack of support from the public authorities: less than 3% of rural development policy funds were allocated to this industry from 2014 to 2020. These tools are particularly underdeveloped for the production from organic farming.

Indicators

- Number of processing units in the territory

- Volumes processed by product type

- Storage capacities for basic food products